- Recruitment

- Right people for NSV

- NSV PEOPLE

- Task

- HR System Welfare

Development of vibration isolation materials, facility vibration isolation equipment, silencers, water hammer cushions, execution of national research projects, complementation and improvement of products.

Product Introduction

Product Introduction

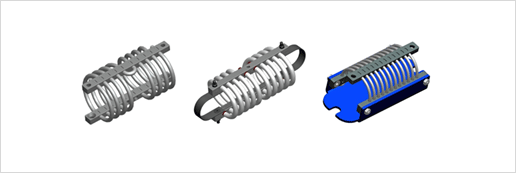

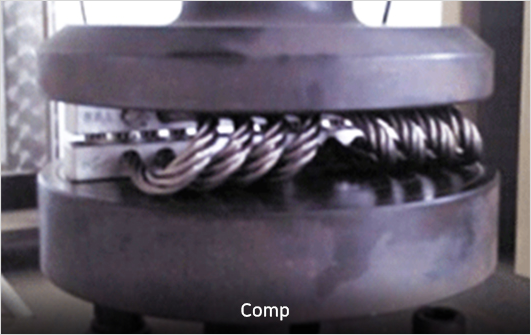

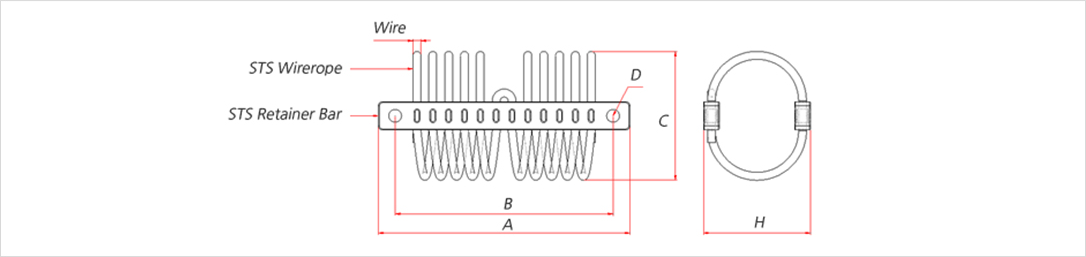

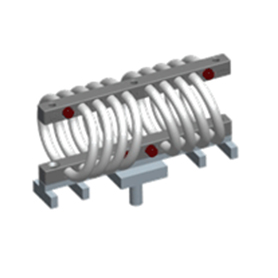

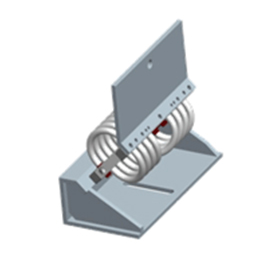

As an isolator using elasticity and the damping effect of wire rope, this plays the role of a snubber that prevents vibration and a shock absorber that eases shock. Our company develops products that meet various needs by making mounts in various ways using such characteristics of wire rope. A useful mount that prevents vibration caused by exciting forces from being transmitted outside through a supporting part and reduces the dynamic displacement on equipment. Its softening characteristic, in which stiffness is reduced according to the increase of displacement, and the damping effect that occurs due to friction damping between wires are both excellent characteristics.

VWM type

VWM type

VWR type

VWR type

VWA type

VWA type

VWS type

VWS type

Isolator that can absorb shock as well as vibration at once

Isolator that can absorb shock as well as vibration at once

All materials are made of stainless steel for excellent corrosion resistance and rigidity

All materials are made of stainless steel for excellent corrosion resistance and rigidity

Surging does not occur due to the high damping function and the transmission rate of vibrations is minimized.

Surging does not occur due to the high damping function and the transmission rate of vibrations is minimized.

Stiffness can be changed according to design and handling methods.

Stiffness can be changed according to design and handling methods.

Horizontal vibration is effectively controlled.

Horizontal vibration is effectively controlled.

Excellent for blocking high-frequency cutoff effects of 100Hz and above

Excellent for blocking high-frequency cutoff effects of 100Hz and above

Excellent heat-resistance, ozone-proof, anti-corrosion, oil-resistance

Excellent heat-resistance, ozone-proof, anti-corrosion, oil-resistance

Equipment requiring vibration isolation for performance and dynamic stability

Equipment requiring vibration isolation for performance and dynamic stability

Equipment requiring shock-absorption

Equipment requiring shock-absorption

Precision equipment installed and moving inside a container

Precision equipment installed and moving inside a container

Precision equipment installed in submarines and ships

Precision equipment installed in submarines and ships

Air conditioning equipment installed on rooftop such as of cooling towers and freezers

Air conditioning equipment installed on rooftop such as of cooling towers and freezers

Registration No.: 10-1362924, 10-1362926, 10-1362927

Registration No.: 10-1362924, 10-1362926, 10-1362927

| Model | Dimensions, mm | Max. Dynamic Travel, mm |

Max. Load, kgf |

|||||

|---|---|---|---|---|---|---|---|---|

| A | B | D | C | H | Wire | |||

|

VWM-04-100 VWM-04-200 VWM-04-300 |

125 | 110 | 6.5 |

45 55 65 |

35 45 55 |

4.0 |

13 16 30 |

90 60 50 |

|

VWM-05-100 VWM-05-200 VWM-05-300 |

125 | 110 | 6.5 |

45 55 65 |

35 45 55 |

5.0 |

13 16 30 |

200 140 90 |

|

VWM-06-100 VWM-06-200 VWM-06-300 |

150 | 134 | 6.5 |

60 70 80 |

50 60 70 |

6.0 |

15 25 35 |

240 170 110 |

|

VWM-08-100 VWM-08-200 VWM-08-300 |

190 | 170 | 8.5 |

80 100 120 |

70 90 110 |

8.0 |

25 45 65 |

270 200 160 |

|

VWM-10-100 VWM-10-200 VWM-10-300 |

250 | 230 | 8.5 |

110 130 150 |

90 110 130 |

10.0 |

50 60 75 |

300 240 150 |

|

VWM-12-100 VWM-12-200 VWM-12-300 |

250 | 230 | 8.5 |

130 150 170 |

110 130 150 |

12.0 |

55 70 95 |

600 550 400 |

|

VWM-16-100 VWM-16-200 VWM-16-300 |

320 | 280 | Φ11.0 |

110 130 150 |

130 150 170 |

Φ22 |

55 70 95 |

1300 1000 800 |

|

VWM-22-100 VWM-22-200 VWM-22-300 |

420 | 380 | Φ11.0 |

130 150 170 |

140 165 190 |

Φ22 |

50 70 90 |

1500 1300 1100 |

Lifetime

Lifetime

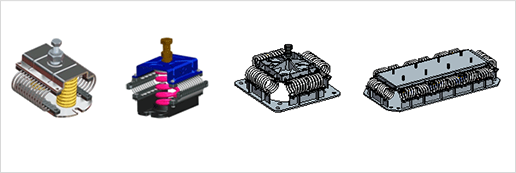

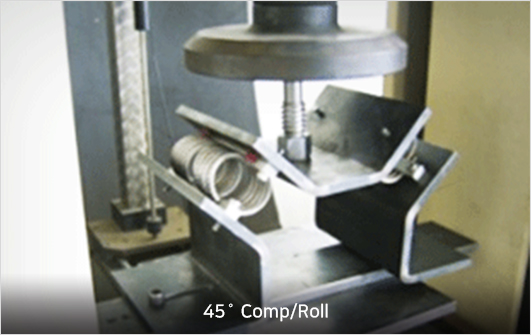

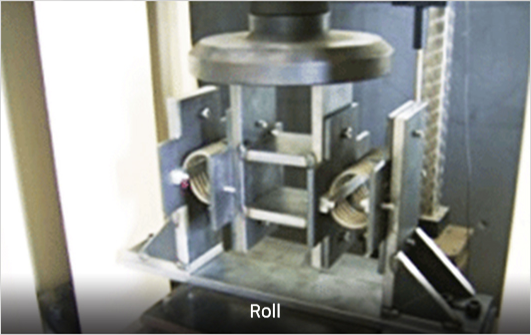

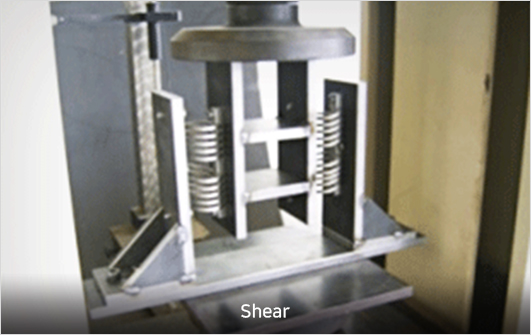

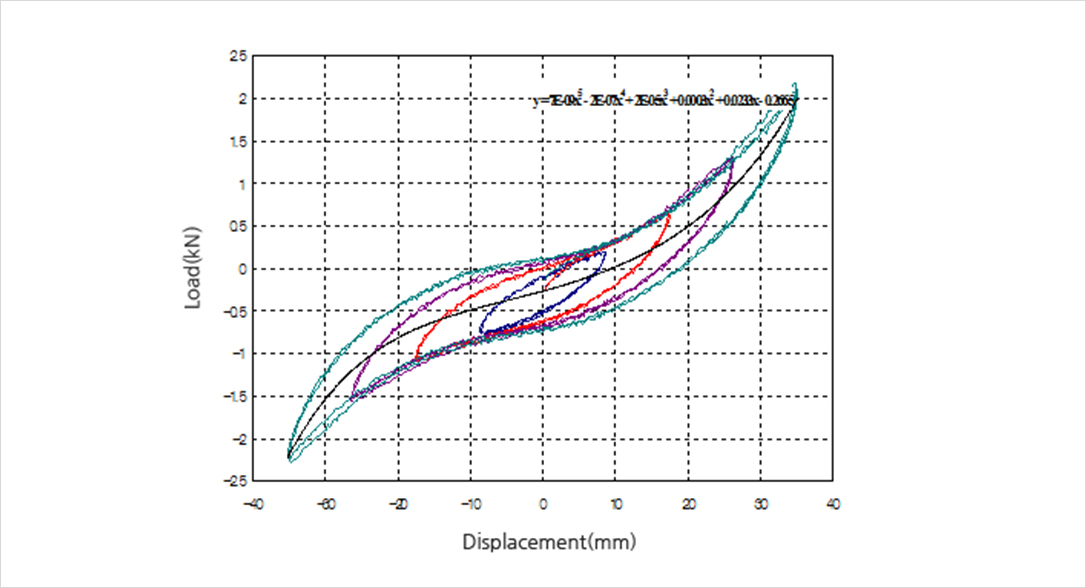

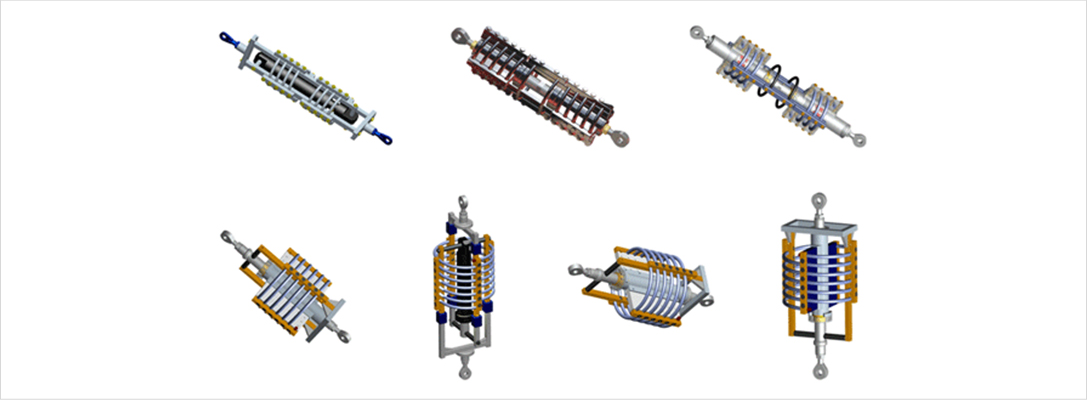

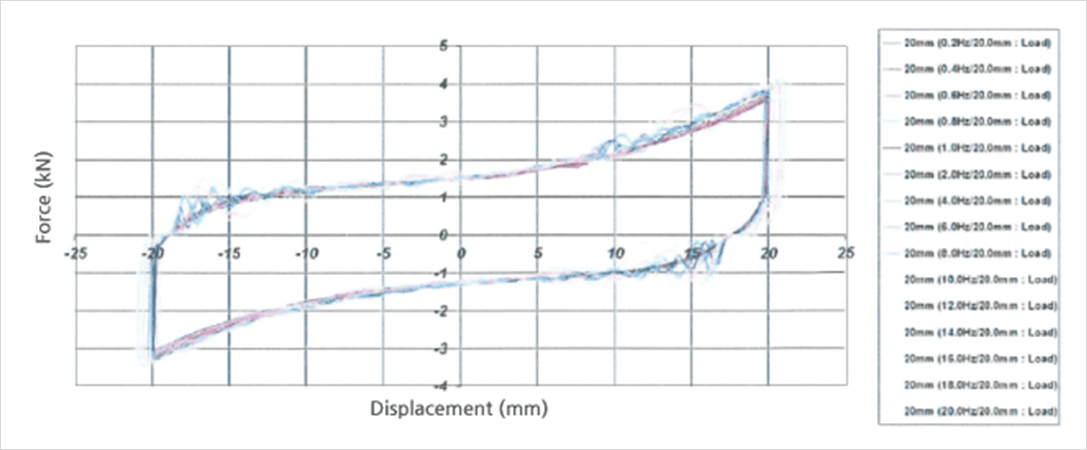

Damper is the general term that refers to things that eliminate vibration energy by converting it into liquid viscosity or material friction. Our company has developed an integrated total damper by combining a friction damper with excellent damping effect and a wire damper, complementing weaknesses and maximizing strengths. As a result of the dynamic characteristics, the damping effect and elasticity were doubled and anti-corrosion and durability were also improved as all materials were made of stainless steel. Also, it was designed for assembly to respond to various strokes and reaction forces.

Total Damper

Total Damper

Excellent damping effect in all frequency ranges

Excellent damping effect in all frequency ranges

Constant damping effect regardless of the size of the vibration displacement

Constant damping effect regardless of the size of the vibration displacement

Structure that can change stroke and reaction force freely as required in design

Structure that can change stroke and reaction force freely as required in design

Compact integrated structure

Compact integrated structure

All materials are made of stainless steel for excellent corrosion resistance and durability.

All materials are made of stainless steel for excellent corrosion resistance and durability.

Excellent heat-resistance, ozone-proof, anti-corrosion, and durability

Excellent heat-resistance, ozone-proof, anti-corrosion, and durability

Pipe with large thermal expansion deformation

Pipe with large thermal expansion deformation

Equipment with large dynamic displacement due to self-vibration

Equipment with large dynamic displacement due to self-vibration

Securement of pipe soundness by controlling pipe dynamic displacement

Securement of pipe soundness by controlling pipe dynamic displacement

Registration No.: 10-1362938

Registration No.: 10-1362938

Product Introduction

Product Introduction

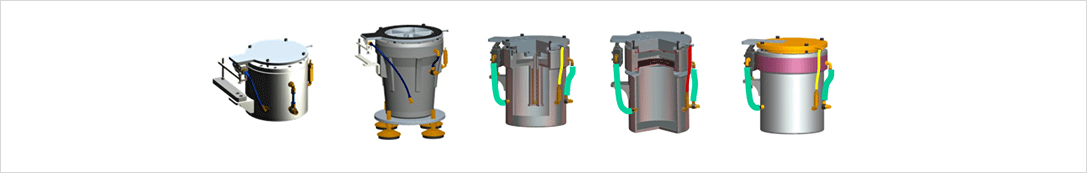

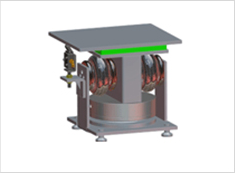

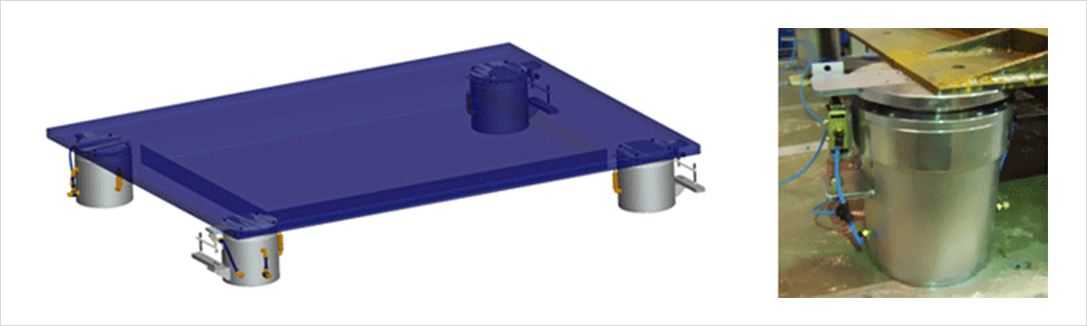

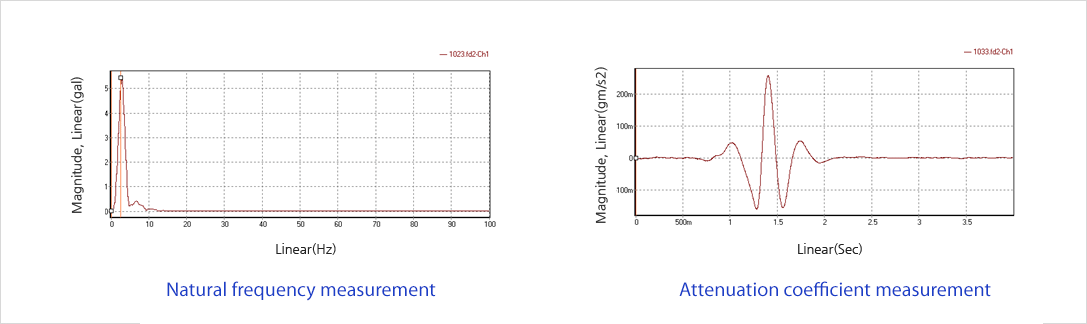

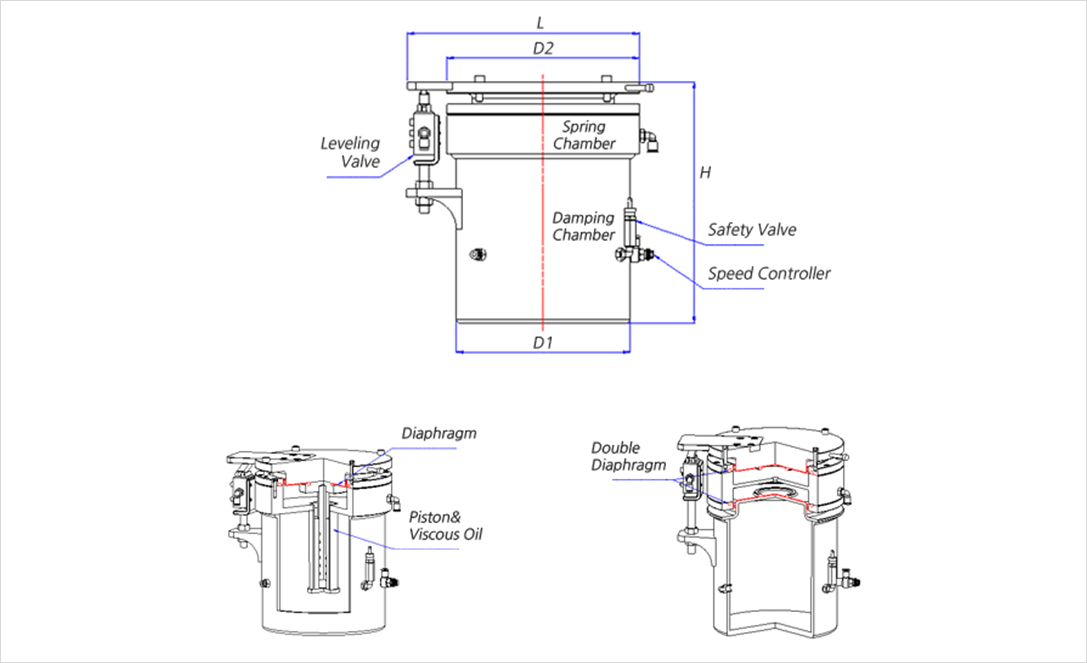

An air spring with excellent vibration insulation efficiency, usually used for controlling low vibration of 1㎛ or less and low frequency vibration less than 1㎛. The air spring is usually used in ultra precision equipment such as semiconductor equipment as its natural frequency is low and there is no surging. Our company is developing various kinds of air spring mounts using air elasticity in order to make the air spring used in various equipment. By damping equipment in various ways, it is promoting dynamic safety and quick stability of equipment without the installation of dampers. VAM Type is a closed air spring, which can be used easily without air line connection. It is suitable for damping precision equipment as it has a low natural frequency of 2.0 Hz or less. With its long stroke, VAB Type has been developed to be suitable for the vibration isolation of equipment with occasional heavy vibration. In particular, VZD type can have a more excellent effect than an active system as it can acquire a natural frequency of 1 Hz or less by applying the principle of negative stiffness.

VAD type

VAD type

VAM type

VAM type

VAB type

VAB type

VZD type

VZD type

Precision semiconductor manufacturing equipment

Precision semiconductor manufacturing equipment

Precision examination and measurement equipment such as 3D measurer or scanner

Precision examination and measurement equipment such as 3D measurer or scanner

Vibration controller installed in FAB

Vibration controller installed in FAB

Precision equipment that needs auto leveling

Precision equipment that needs auto leveling

Equipment that requires blocking of surrounding vibrations

Equipment that requires blocking of surrounding vibrations

Registration No.: 10-1362928, 10-1362930

Registration No.: 10-1362928, 10-1362930

| Model | Applied load, kgf | Dimensions, mm | |||

|---|---|---|---|---|---|

| D1 | D2 | H | L | ||

| VAD-120 | 300 | 120 | 120 | 160 | 170 |

| VAD-180 | 800 | 150 | 180 | 220 | 220 |

| VAD-240 | 1,500 | 220 | 240 | 300 | 290 |

| VAD-300 | 3,000 | 270 | 300 | 300 | 350 |

| VAD-380 | 5,000 | 350 | 380 | 300 | 430 |

| VAD-500 | 10,000 | 460 | 500 | 300 | 550 |

| VAD-680 | 20,000 | 640 | 680 | 300 | 730 |

Product Information

Product Information

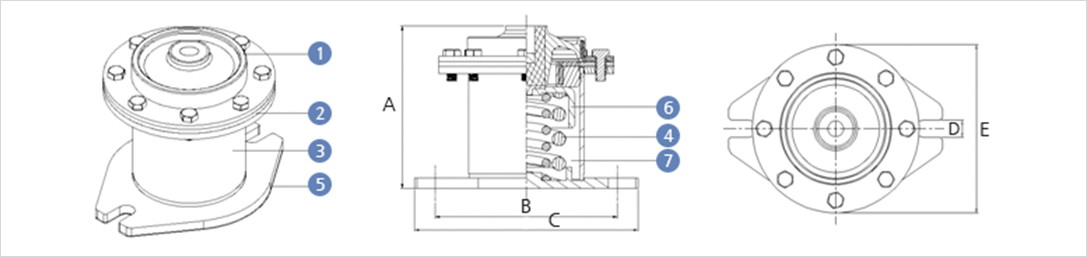

This is an integrated mount that has an excellent effect on impact force and regular vibrations by combining only advantages of an oil-filled damper with those of springs and rubber. In the primary damping, impact vibration is dissipated into friction heat energy through oil and the primary regular damping of exciting force is reduced by rubber part and spring. The upper rubber part is manufactured with CR (neoperene) synthetic rubber, which has great oil and ozone resistance. As apical displacement of the spring occurs after product assembly, a low frequency of less than 5Hz can be maintained.

For high-efficiency vibration isolation of cooling tower

For high-efficiency vibration isolation of cooling tower

For vibration isolation of heavy and high-efficiency equipment (Semiconductor Production Line)

For vibration isolation of heavy and high-efficiency equipment (Semiconductor Production Line)

For vibration isolation of equipment with great impact vibration

For vibration isolation of equipment with great impact vibration

For vibration isolation of equipment sensitive to ambient impact force and vibrations

For vibration isolation of equipment sensitive to ambient impact force and vibrations

| No. | Product name | Material | Standard |

|---|---|---|---|

| 1 | Upper Cap | CR&GC | KS M 6617, KS D 4301 |

| 2 | Middle Cap | CR&GC | KS M 6617, KS D 4301 |

| 3 | Lower Housing | SS40 | KS D 3503 |

| 4 | Coil Spring | SUP9, HSW3 | KS B 2402, KS B 2403 |

| 5 | Non Skid Pad | CR | KS M 6617 |

| 6 | Inner Damper | GC | KS D 4301 |

| 7 | Damper Oil | - | FLUID OL |

| Model | Rated Load, kgf | Dimensions, mm | |||||

|---|---|---|---|---|---|---|---|

| A | B | C | D | E | Level Bolt | ||

| VDM-500 | 500 | 160 | 149 | 184 | 18 | 124 | M12 |

| VDM-1000 | 1,000 | 160 | 149 | 184 | 18 | 124 | M12 |

| VDM-1500 | 1,500 | 197 | 220 | 270 | 22 | 212 | M20 |

| VDM-2000 | 2,000 | 197 | 220 | 270 | 22 | 212 | M20 |